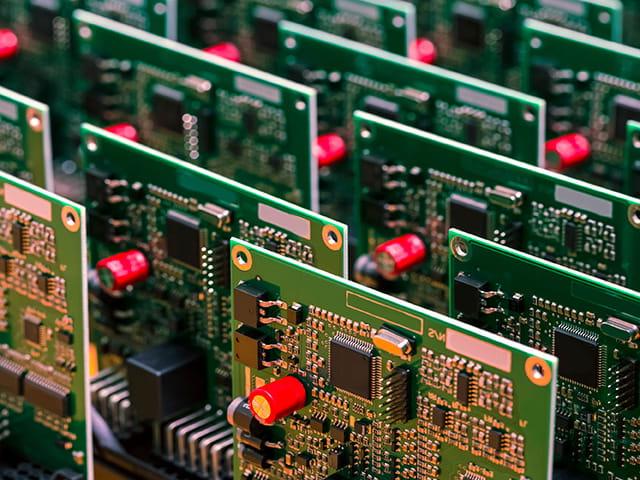

Determine whether your device components can be successfully soldered during the assembly process with industry-leading solderability testing from im体育APP.

Solderability testing is an important step in determining whether your electronic device can be efficiently manufactured. This type of testing determines the solderability of device package terminations that are intended to be joined to another surface using lead- (Pb-) containing or Pb-free solder. The process involves destructive tests that indicate whether the 包装 materials and processes used during manufacturing produce a component that can be successfully soldered in the next level of assembly.

There are two 方法 of solderability testing. Method one is known as “dip and look” (D&L) which is for leaded and leadless terminations. This method includes pre-conditioning, 如果适用的话, the application of flux, and the immersion of the terminations into molten solder. Method 2 is a surface mount process simulation test that applies solder in a way consistent with the intended final assembly of the product.

Wetting balance test

Solderable surfaces differ in the speed and strength of their adhesion. The wetting balance refers to the time required for the solder to wet the component termination or pad, which is an important factor in solderability. The wettability of a surface is influenced by the type of metal or contaminants present. It is often used in testing for counterfeit parts, as resurfaced leads will react differently than new parts.

The wetting balance test can be performed on leaded or leadless components. Leaded components use a molten solder bath and for leadless parts, a globule of solder is used instead. Many specifications require some kind of preconditioning, 比如蒸汽年龄, prior to testing to simulate shelf life and show solderability and wettability after long periods of storage.

Some of the specifications and 方法 for wetting balance testing are:

- ANSI j - std - 002

- ANSI j - std - 003

- 883年为基础

- ISO 9455 - 16

- ISO 12224 - 3

- Jis z 3198

Solderability testing standards & 方法

We test to your specific requirements, but the standards and 方法 typically used for solderability testing are:

- IPC / ECA j - std - 001

- j - std - 002

- j - std - 003

- MIL-STD-202, Method 208

- 883年为基础, Method 2003.10

- IPC-TM-650, Method 2.4.12

Solderability test 方法 establish preconditioning and soldering options to assess the solderability of device package terminations. They provide procedures for “dip and look” (D&L) solderability testing of through hole, 轴向, and surface mount devices and a process simulation test for surface mount packages.

Why choose im体育APP?

im体育APP provides comprehensive electronic component testing for PCBs and related device components. Our experts have the experience, 设备, and facilities necessary to provide you with the best testing and certification services in the industry. 立即im体育APP to speak with an expert about your specific needs.

了解更多

Printed Circuit Board (PCB) Failure Analysis

Understand and rectify the root causes of PCB failure with industry-leading PCB failure analysis from the testing experts at im体育APP.

Printed Circuit Board 测试

Ensure your printed circuit boards and finished printed circuit assemblies are of the highest quality and compliant with relevant standards with comprehensive PCB testing from im体育APP.

Consumer Electronics 测试 & 认证

im体育APP’s consumer electronics testing and certification services help your products meet EMC, 电气安全, 和国家广播电台 & global requirements.

电气安全 测试 and 认证

Discover how im体育APP combines its range of electrical testing with EMC, radio, wireless and IoT compatibility services to get your products to market faster.