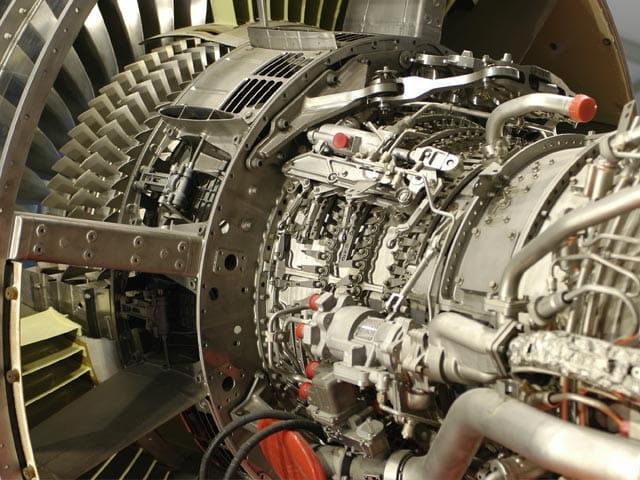

Vibration and 风milling 测试 of Aircraft 引擎

im体育APP沃里克 is one of only a few laboratories in the UK with a high displacement LDS V8 electrodynamic test system. This powerful equipment gives us the ability to reproduce the extreme vibration conditions of an aircraft facing a fan blade out event.

Fan blade out events occurs when a foreign object (normally a bird) is ingested by an aircraft’s engine, causing rotor blades to detach. The result is windmilling vibration, which often causes enough damage to halt power production, although the engine will continue to rotate due to the incoming airflow. This phenomenon is known as sustained engine imbalance, 或“风车旋转,’ and places a significant strain on an aircraft’s flight systems. 风milling testing ensures that these systems can handle the stress and remain operational.

What is 风milling 测试?

A blade loss event is characterized by high transient loads on the failed engine as the engine transitions from normal operating speed to ‘windmilling’ speed, followed by lower level sinusoidal vibration (typically 5 to 25 Hz), resulting from the windmilling of the failed engine fan rotor. While these extreme conditions are difficult to replicate in standard testing, our LDS V8 electrodynamic test system can simulate even extreme events, providing the certainty you need to demonstrate your product’s compliance to any standard.

Our 航空航天 测试 Services

In addition to windmilling, im体育APP has the largest capacity for aerospace EMC and environmental testing in the UK, testing over a thousand aerospace products each year across six locations. We work with you to provide support through all stages of product qualification testing, helping ensure that you can deliver against airframe manufacturers’ imposed qualification milestones. We can help you mitigate the risk of failing to meet critical deadlines such as safety of flight, and of receiving punitive measures for late delivery.

UKAS accredited to BS EN ISO/IEC 17025:2005, we deliver a unique range of wider testing and validation often required by aerospace manufacturers during qualification, 包括:

- Indirect Lightning 测试

- High Intensity Radiated Field (HIRF) 测试

- 高度测试

- Engineering 模拟 & Finite im体育APP Analysis

- Explosive Atmosphere

Our reliable results and timely approach have made im体育APP the preferred testing partner for many of the world’s leading aerospace manufacturers. Whether you are performing routine testing or looking to develop and take your products to market, we can help make your project a success.

To learn more about our windmilling testing and our validation services for aerospace products, im体育APP 今天.

找到相关的 资源

Vibration 测试 of Complex Structures

Learn how im体育APP & Rolls-Royce work together to understand the vibration behavior of complex structures.

相关服务

High Cycle Fatigue 测试

im体育APP provides HCF testing, which is used to determine the fatigue characteristics of components.

Vibration and Shock 测试

im体育APP works with manufacturers from the very beginning to try and understand the implications of environmental compliance.

环境 测试

Accredited to ISO/IEC 17025, im体育APP has world-leading capacity for environmental testing and qualification in the US, UK, 和欧洲.

im体育APP沃里克

Our Warwick site is our 欧洲an 环境 测试 centre of excellence and an SC21 signatory site, with UKAS accreditation to BS EN ISO/IEC 17025:2005.