Using Finite im体育APP Analysis (FEA) to Identify Delamination of Composites Materials

Delamination is an important factor to consider when testing composites, particularly when comparing this to metallic materials.

的分层 复合材料 can be caused by high interlaminar stresses in conjunction with low through-thickness strength which puts 复合材料 at greater risk of failure.

Types of delamination

Delamination is a common failure that leads to the separation of the layers or the reinforcement within the composite material. Delamination failure can be caused by a fracture in the adhesive, 树脂, or within the reinforcement, or it can be caused by debonding of the 树脂 from the reinforcement.

The example below uses advanced Finite im体育APP Analysis (FEA) to look at delamination of a bolted joint due to an overload during operation.

How to prevent delamination in 复合材料

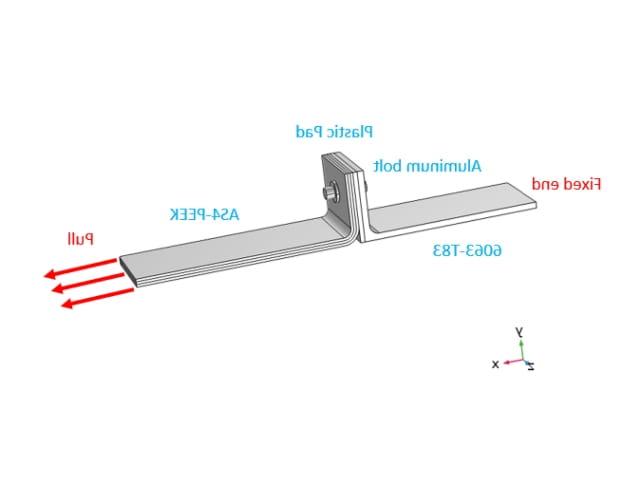

Using the FEA method, 我们可以模拟 the delamination of the structural component. In the example below we look at the structural evaluation of a multi-layered composite flange (AS4-PEEK) under dynamic loading.

The diagram illustrates the dynamic assessment of a composite flange connected to an aluminum grade, heat-treated part (Al063-T83), which is separated by a plastic spacer 和 kept in place using aluminum bolts.

The composite flange has a steep radius which is a critical location for delamination initiation as the laminate has reduced capacity for out-of-plane loading.

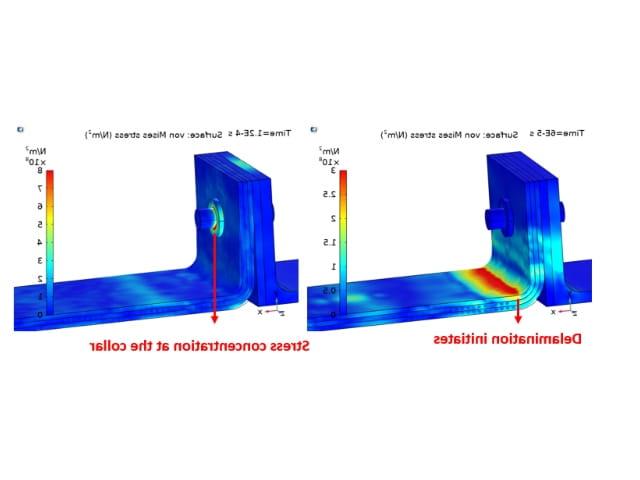

运用有限元分析, 我们可以模拟, 和 confirm the concern over the delamination initiation in the loading phase at a small flange opening angle, as well as stress concentration in the collar.

We can use this to study 和 simulate, design improvements such as increasing the composite thickness, using a crushable bolt collar that absorbs energy through its deformation, or testing a different flange architecture. Using traditional FEA of 复合材料 和 parts, it enables us to:

- Predict critical failure events such as delamination 和 debonding at the locations of interest.

- Size the flange parts to optimize the design by increasing loading capacity, 减肥, 这就是成本.

- Create a digital replica, or 数字双 of the dynamic test 和 use that to reduce qualification costs.

The im体育APP advantage

在im体育APP,我们的 数字工程 和 复合材料测试 experts work in partnership 和 assist clients from verification to validation, throughout the entire product life-cycle, 确保材料, products 和 components are at the forefront of innovation, 和 perform as expected. Contact our team today to learn more.

找到相关的 资源

相关服务

聚合物测试

im体育APP performs a range of mechanical, 电, flammability tests 和 utilizes thermal analysis tests to characterize the composition of polymers 和 复合材料.

材料测试

Find out more about im体育APP's comprehensive ranges of materials testing services available in the TIC sector, covering materials selection, application 和 performance testing as well as failure analysis testing services.

建模 和 模拟

We specialize in modeling 和 simulation to accelerate your research 和 development initiatives, optimize your designs 和 support safe, 高效的操作.