材料在低温下的行为

Introduction to Relevant Physical Phenomena and 材料在低温下的性能

The behavior of metallic materials under cryogenic temperature conditions throughout 低温测试 differs significantly from their behavior at room temperature for the same type of test. This is due to various physical phenomena that become relevant when the temperature reaches that of liquid nitrogen (-196° C) or falls further when approaching the temperature of liquid helium (approximately -267° C).

The following is a qualitative description of typical behavior that occurs at low temperatures. 这个故事, 虽然很简单, attempts to give an account of what is evident during laboratory tests.

1. 热容

Among the most relevant effects at cryogenic temperatures is the heat capacity at constant volume (Cv). 在等体积条件下, the primary contribution of the temperature (T) variation is the variation of the internal energy (U) of the body concerned. 因此,其值可以表示为:

达到足够的近似程度, it can be stated that the molar-specific heat at temperatures around and above room temperature for almost all solids is constant and independent of temperature. In accordance with Dulong Petit’s law it is approximately equal to:

其中R为摩尔气体常数(≈8.314 J mol-1K-1).

当我们接近低温条件时,这个定律就不适用了, 量子现象在哪里变得越来越重要. 温度低于20到30开尔文, Dulong and Petit’s law ceases to be applicable and other models such as the Debye integral must be considered.

Basically, these statistics agree that the specific heat tends to zero (or at least to very low values as in Einstein’s model) as the temperature approaches absolute zero.

可以从C的表达式中推断出来v 上面是很低的C音v value causes strong temperature variations even for small variations in internal energy ∆U, potentially generating thermal instability phenomena in the material in the question of sufficient intensity to contribute to structural variations in the lattice.

2. 脱位的活动性降低

The second relevant phenomenon at low temperatures is the reduction in the mobility of dislocations within the solid matrix, which is progressively less favored by temperature-related transport mechanisms.

This reduced mobility further favors the piling up of dislocations close to obstacles already present in the lattice (e.g. 存在洛默-科特雷尔位错, 可以在fcc型晶格中形成的, 例如在奥氏体钢中).

The piling-up process proceeds until the energy stored at the barrier exceeds the energy of the barrier itself. At that point, a collapse of the structure occurs with a rapid release of the stored internal energy. If during the stacking phase the change in internal energy ∆U remains limited, the collapse of the barrier causes a significant release of this energy which, with Cv 在低温下非常低, consequently causes a rapid temperature peak that can be of the order of tens of degrees.

The energy released triggers avalanche phenomena at most of the blocked sites, 鼓励重复同样的现象.

At a macroscopic level, the above becomes evident and visible in the results of laboratory tests.

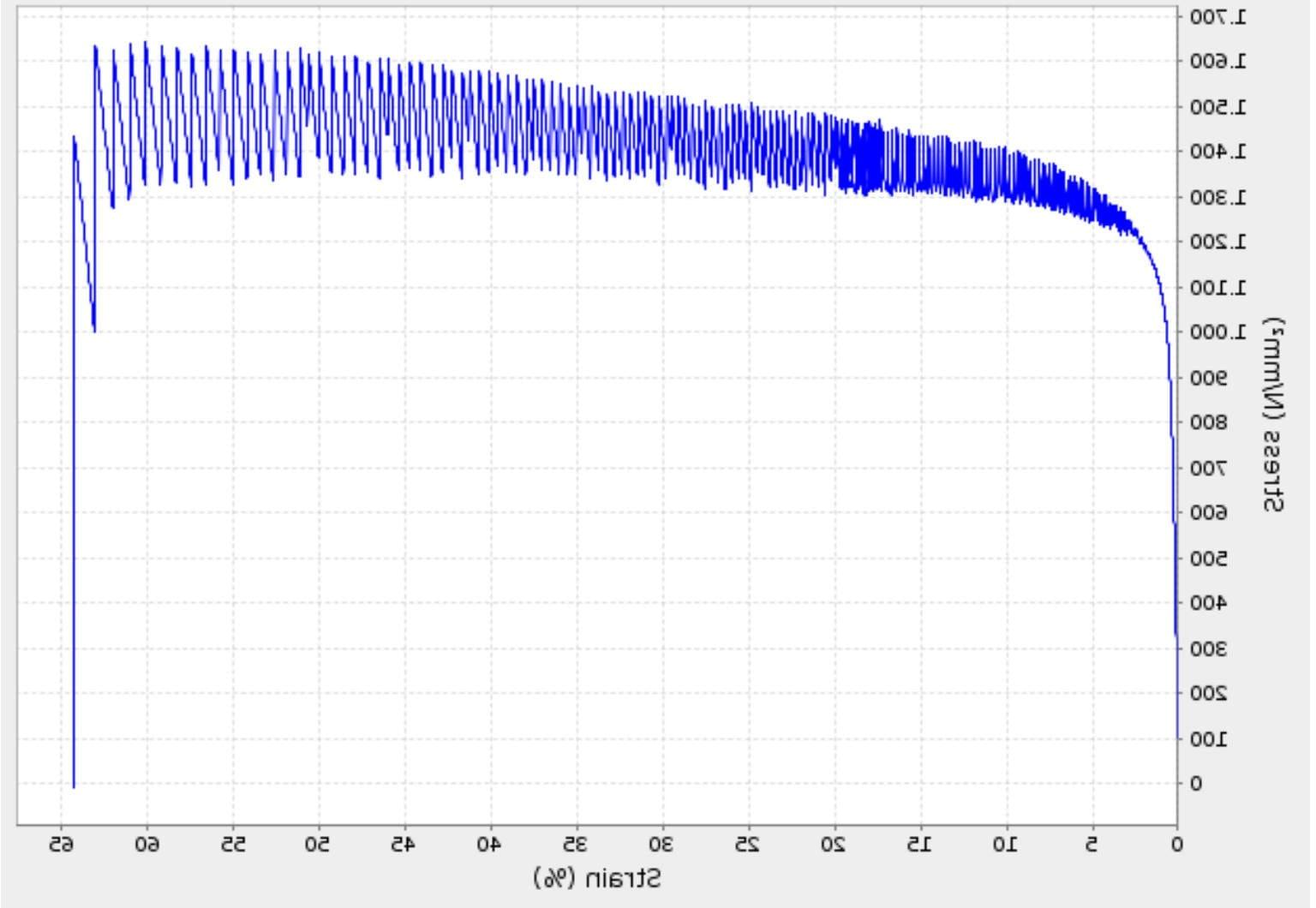

特别是a的应力应变图 拉伸试验 呈典型的锯齿状, 具有强烈而频繁的振荡, each associated with the phenomenon of energy accumulation and release described above (Figure 1). These oscillations can affect a significant percentage of the graph area, 在许多情况下从10%到30%的总伸长率.

3. 材料硬化

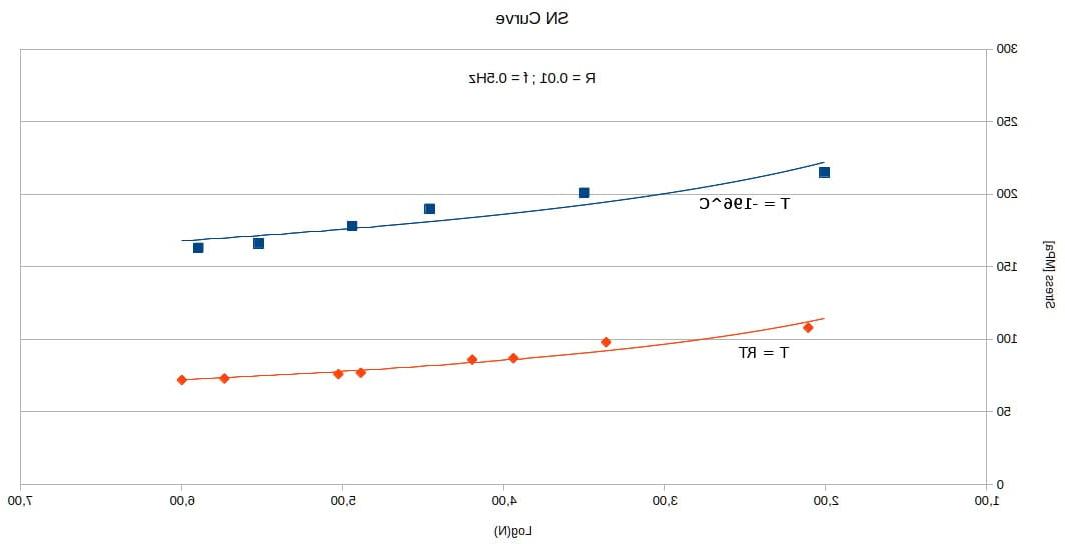

一种众所周知的现象,发生在周期 疲劳测试 是材料的硬化吗. This phenomenon becomes particularly relevant and clearly visible even at -196° C. In Figure 2 it is evident that the endurance to cyclic loading at -196° C is much better than the same test at room temperature.

The hardening phenomenon is particularly evident in austenitic steels, 常伴有奥氏体-马氏体转变. 应该指出的是, 因为马氏体是铁磁性的(而奥氏体是抗磁性的), this transformation becomes particularly critical in applications involving the presence of particularly high magnetic fields.

4. 低温夏比试验

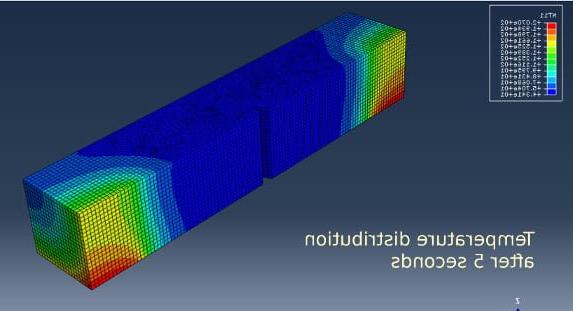

本文中考虑的最后一个测试是 夏比测试. 有限元模拟 performed at im体育APP米兰 show that the test technique is usually used as described in ISO148 and ASTM E23, 其中包括将样品冷却到所需的温度, 将样品转移到测试机器, 5秒内进行冲击测试. 但它不适用于极低的温度.

In fact, it can be seen that 5秒后 the temperature at the notch increases by at least 42 Kelvin just by extracting the sample from the dewar, bringing the effective test temperature for steel to about -228° C. 最糟糕的情况是铝, where, 5秒后, 温度达到62开尔文左右, 从而使测试温度达到-211°C左右.

采用的解决方案 im体育APP米兰 for 夏比测试s at very low temperatures is to perform the test under conditions of continuous helium flow.

This dramatically limits the temperature rise due to the transfer of the sample from the dewar to the test system. 这使我们能够保证-267°C的标称温度, 不确定度约为20开尔文.

了解更多关于我们的 低温检测服务, please im体育APP的团队 今天的专家.

找到相关的 Resources