常见问题:什么是氢脆?

专职专家

Vikram南达拥有超过20年的经验, 维克拉姆领导着一个由故障分析师和冶金学家组成的团队, providing technical support and expert opinion on Metallurgical Failure Investigation at Element's UAE region.

我们询问了我们的冶金和失效分析专家 Vikram南达 to answer the Frequently Asked Questions he and his team receive daily regarding hydrogen embrittlement. 阅读下面他的回答来发现原因, 影响, 防止氢脆, 还有更多.

什么是氢脆(HE)?

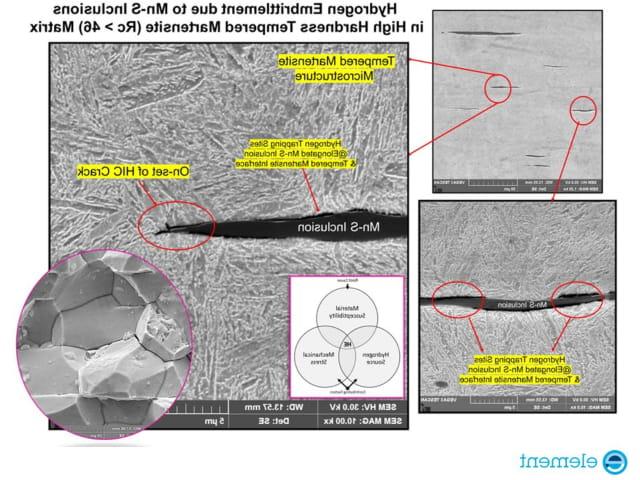

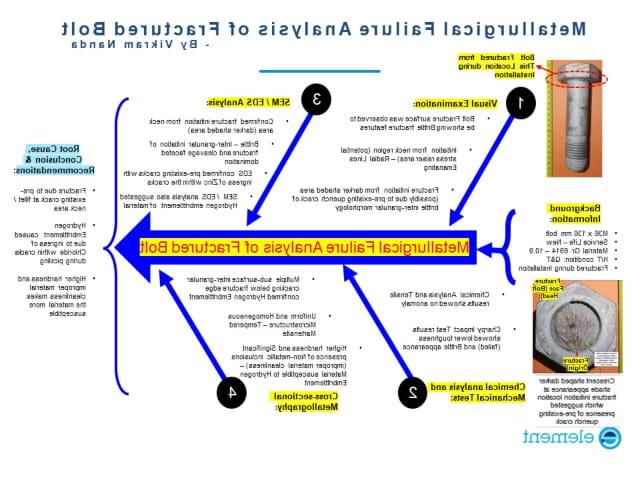

氢 Embrittlement (HE) is characterized by a loss of ductility and strength due to the absorption of hydrogen atoms by the metal, 最终沿晶界扩散, 弱化物质结构, 促进晶间开裂. 随着金属强度的增加, 钢变硬了, 更少的韧性, 更少的困难, 变得更容易受到HE的影响. The result of hydrogen embrittlement is that steel components crack and fracture by brittle morphology at stresses less than the yield strength of the metal.

什么是钢/不锈钢的氢脆?

氢 embrittlement occurs most notably in high-strength steels, while 不锈钢 are known to be relatively less susceptible to hydrogen embrittlement but not totally immune to HE. 氢 embrittlement is essentially a loss of ductility and reduction of load-bearing capability of a relatively ductile metal due to the absorption of hydrogen atoms into the metal either during manufacturing, 制造, 或者在服役. 氢原子很小,很容易渗透到固体金属中.

一旦吸收, atomic hydrogen recombines in the various trapping sites like voids/inclusion sites or internal defects in the material to form hydrogen molecules (H2), 从金属内部产生压力. This pressure can increase to the levels where cracks initiate and eventually lowers the stress required for these cracks in the metal to propagate, 导致脆化(脆性断裂).

螺栓中的氢脆是如何发生的?

氢 embrittlement (HE) in high-strength steel bolts of property classes 10.9 & 12.9 is known to happen primarily due to changes in material behavior by atomic hydrogen. 结果是, this may lead to brittle fracture under tensile load caused by the tightening procedure or during in-service conditions.

氢脆温度是多少?

氢 embrittlement (HE) is a near-ambient temperature phenomenon. HE gradually diminishes when the temperature is higher than 100°C.

什么导致氢脆?

氢 embrittlement is caused by the absorption of hydrogen atoms into a material having hydrogen trapping sites within the microstructure. This can lead to a loss of ductility and toughness under applied or residual stresses and promote cracking and brittle fracture at stress level which is less than the yield strength of the metal. 氢原子的来源可能是腐蚀反应, 电镀过程, 酸洗, or 制造 processes like welding by using damp welding rods. 一般来说,高强度材料更容易受到HE的影响.

“The biggest challenge with hydrogen embrittlement is that it can be difficult to detect and predict. The process of hydrogen embrittlement can occur slowly over time and may not be immediately apparent until a component fails catastrophically. ”

Vikram南达

冶金 & 冶金失效分析专家

How to prevent hydrogen embrittlement in electroplated fasteners?

One of the most common procedures to prevent hydrogen embrittlement is through a process called baking. Baking normally consists of heating the electroplated fasteners to a specified temperature and holding them at a temperature generally between ~180 - ~220ºC for a period of 8 to 24 hours.

哪种金属最容易氢脆?

氢 embrittlement (HE) does not affect all metallic materials equally. The most vulnerable materials are high-strength steels (such as those used in the 航空航天 and 汽车 im体育平台app下载), as well as titanium and cobalt alloys whereas other materials such as copper, 铝, 不锈钢, 还有一些镍合金, 对HE的易感性较低. 然而, if these materials have gone through a strain-hardening process, 然后它们可能会受到氢脆的影响.

Chrome plating, zinc plating, and electroless nickel plating may also cause HE. It is important to note that the vulnerability of material to hydrogen embrittlement can be affected by a variety of factors, 例如材料中杂质的存在, the level of hydrogen exposure during manufacturing/制造 或者在服役, 应力水平(施加和/或残余), and the temperature and pressure conditions in which it is being used.

如何识别氢脆?

The most effective inspection methods to identify hydrogen embrittlement cracking are 磁粉检测(MPT) and 超声波检测(UT). MPT对于识别表面裂纹特别有用, however, 根据我的经验, 对小型紧固件实施MPT, 可能是个挑战.

Element如何提供帮助?

Element laboratories in the UK, US, and Middle East can perform mechanical 氢脆试验 符合ASTM F519. The test specification outlines the use of Sustained Load Testing (SLT) to measure the possibility of hydrogen embrittlement in steel materials by applying uniaxial tension for up to 200 hours.

im体育APP to learn more about how we perform 氢脆试验.

找到相关的 资源

“The greatest benefit of conducting 氢脆试验 is that it helps to ensure the safety and reliability of critical components that are subject to high stress and exposure to hydrogen, 比如在航空航天中使用的那些, 汽车, 能源im体育平台app下载. ”

Vikram南达

冶金 & 冶金失效分析专家

相关服务

氢脆试验

Element performs 氢 Embrittlement (HE) testing to ASTM F591, Galvanically Induced 氢 Stress Cracking (GHSC) to NACE MR0175/ISO 15156 and 氢 Induced Stress Cracking (HISC) testing.

超声波检测(UT) & 检查服务

Ultrasonic testing (UT) is a non-destructive test method that utilizes sound waves to detect cracks and defects in parts and materials. 它也可以用来确定材料的厚度, 比如测量管道的壁厚.

磁粉探伤

了解更多关于磁粉检测的信息, 有时称为MT, MPI, 或者是磁粒子, a nondestructive test method used to check for surface and sub-surface discontinuities and defects.

氢致开裂(HIC)试验

Element’s HIC tests evaluate material susceptibility to hydrogen induced cracking in a sour environment in accordance with NACE TM0284.